First, Dacromet's anti-corrosion mechanism1. Controlled electrochemical protection of zinc on the substrate.

2. Passivation of chromic acid: The usual passivation is only to form a very thin passivation film on the surface of the metal to be treated, such as electroplating, hot plating, and numerous tiny zinc flakes and chromic acid in the Dacromet solution. After the passivation reaction, after the coating is baked, the zinc sheets are layered to form a myriad of passivation films.

3. The mechanical shielding shielding protection of the zinc sheet and the re-chromium salt coating and the "elution" effect of the aluminum inhibiting zinc.

Second, the characteristics of DacroDacromet is an advanced, complete metal surface treatment technology with advantages and features unmatched by other surface treatments:

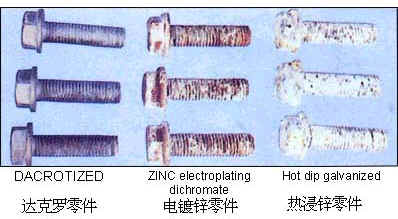

1. Superior corrosion resistance: A myriad of passivation films are formed.

The etched galvanized layer generally etches 1-3um thick Dacromet-treated metal surface in salt spray test for 10 hours, and corrodes 1um in 100 hours after salt spray test, which is more resistant than traditional metal surface treatment. Corrosion is improved by 7-10 times, salt spray test can reach more than 1000 hours, and there is a high technical index against sulfur dioxide, showing stronger rust resistance.

2. Excellent hot corrosion resistance: When the traditional galvanized layer is higher than 70 ЎгC, micro cracks will occur, and it will change color under the condition of 200-300 ЎгC, and the corrosion resistance will be greatly reduced. The curing temperature of Dacromet anti-corrosion film is 300 ЎгC, so the surface metal crucible has the same appearance even if it is kept under high temperature conditions, and the hot corrosion resistance is excellent.

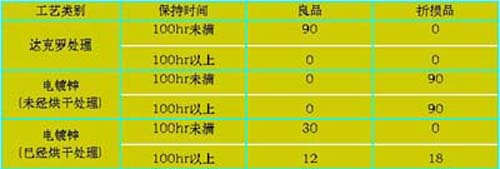

3. No hydrogen embrittlement: Hydrogen embrittlement is a drawback that cannot be overcome by traditional galvanizing processes. No pickling is carried out during the Dacromet treatment. Without acid washing, there is no hydrogen ion eroding the steel substrate, and at the high temperature, the Dacromet coating is absolutely free of hydrogen embrittlement. It is especially used for anti-corrosion treatment of high-strength parts with tensile strength Rm>1000N/sqЎӨmm, such as high-strength bolts and springs.

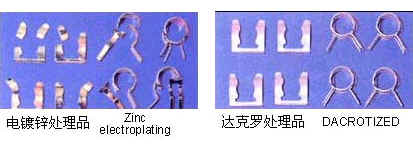

4. High permeability: After the Dacromet-treated metal parts, the film can be formed in fine voids, the anti-corrosion coating with good penetration, the uniform coating in the tubular parts, plus the Dacromet solution. It is water soluble, so its permeability is very good. (The figure below shows the comparison of the results of electrogalvanized products and Dacromet products after 240 hours of salt spray test.)

5. High adhesion: The zinc, aluminum sheet and composite salt coating formed after high temperature baking have good adhesion to the steel substrate.

6. High weather resistance: Dacromet can withstand sulfur dioxide, acid rain, soot and dust at a certain coating thickness. Its resistance to SO2 test can reach 3 cycles. Suitable for workpieces, sea wheels, etc. in maritime climate. In addition, it also has certain resistance to chemical corrosion, and has good corrosion resistance in gasoline and engine oil.

7. Optimized the protective function of corrosion of aluminum electrochemical elements: Generally, when two metals or alloys with different electrode potentials are in contact, electrochemical corrosion will occur, and the anti-corrosion mechanism of galvanizing is the sacrificial corrosion of metal zinc. Corrosion effect, while Dacromet's anti-corrosion mechanism is based on the passivation of Cr acid and the controlled sacrificial protection of zinc, so the mechanism is optimized and the consumption of zinc is suppressed, thereby greatly improving the safety of corrosion resistance. Sex.

8. Low friction: The Dacromet coating after the addition of the lubricant can produce an ultra-low friction of 0.06-0.12 coefficient after proper treatment, and a moderate friction of 0.12-0.18 coefficient after general treatment.

9. Good matching precision: Generally, the Dacromet coating can be controlled between 6-8um, so the matching precision of the fastening body can meet the accuracy requirement of 6g/6n.

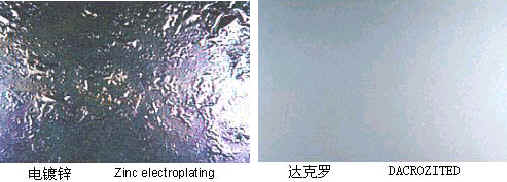

10. Beautiful Yaxing silver-gray coating appearance: The metal surface of the workpiece or part processed by Dacromet technology is matt silver gray, beautiful and generous. Moreover, Dacromet's coated surface has strong adhesion to paints and coatings, and can be repainted on Dacromet's coated surface to form a variety of colors.

Third, the use of Dacromet's inevitability, necessity and benefit analysis1. Since electroplating not only causes serious pollution to the atmosphere, land, and water sources, it is also very harmful to operators. As soon as the country has made three orders and five applications, it is necessary to introduce a new green industry to replace it. Therefore, the demise of the electroplating industry is an inevitable result, and the conversion of electroplated parts to Dacromet is inevitable. In the production process of Dacro, there is no pollution, and it is the real green industry encouraged by the state.

2. It is also necessary to use Dacromet technology for various metal surface coatings. First, because the original electroplated parts have poor corrosion resistance, easy to rust; poor thermal corrosion resistance, easy to deform; poor surface stability of the coating, easy hydrogen embrittlement; second, because Dacromet technology overcomes these shortcomings of electroplating, can do ten No rust over the years, can adapt to the requirements of users, and adapt to the requirements of export products.

3. For parts with high requirements, such as automobiles, motorcycles, aerospace, highway bridges, electrical and electronic parts, etc., electroplating technology cannot be satisfied. It can only be solved by Dacromet technology. Comparable. The emergence of Dacromet technology is a high-tech of metal surface treatment in the world today. It has been praised by experts as a revolutionary product and green engineering with epoch-making significance in the international metal surface treatment industry. She will effectively serve all walks of life at home and abroad.